Tecnar's core technologies and product brands

- Laser-induced breakdown spectroscopy (LIBS)

- Laser ultrasonics

- Thermal and cold spray

- Automated pipe and vessel welding

Laser-induced breakdown spectroscopy

Galvalibs 2.0 and Alulibs by Tecnar

Galvalibs 2.0 and Alulibs by Tecnar

Tecnar’s Laser-Induced Breakdown Spectroscopy (LIBS) analyzers bring bath chemistry analysis from the laboratory to the line. Based on real-time LIBS, its patented technology performs a laser sampling of the molten metal, deep below the surface, yielding a highly accurate, multi-element chemistry analysis. By its nature, dissolved concentrations are measured directly, without the need for temperature information or model-based calculation.

Tecnar’s molten metal analyzer products include:

- Galvalibs 2.0 – the only true multi-element, online, real-time and accurate bath composition analyzer.

- Alulibs – all-in-one analyzer for molten aluminum chemistry

Discover our solution for zinc

Laser ultrasonics

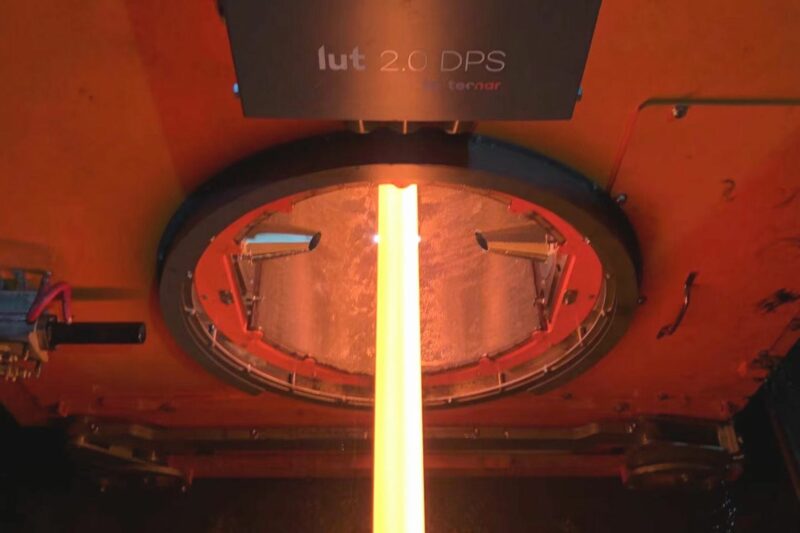

Lut 2.0 by Tecnar

Tecnar has over 20 years of experience implementing non-contact ultrasonic thickness gauges in hot seamless tube mills. The Lut 2.0 brings ultrasound performance to online hot wall thickness measurement with 10µm precision. In addition, it is the only gauge that fully characterizes eccentricity under all plant conditions.

The Lut 2.0 is offered in four different configurations to give you the best features for your application:

- Cross-rolling processes

- Longitudinal processes

- Two-high roll mills

- Three-high roll mills

Lus packages by Tecnar

The Lus product line is a complete set of tools to jumpstart your laser-ultrasonic research and applications.

These Lus products are the essential building blocks for researchers and engineers to apply non-contact ultrasonics to new fields of study, in new environmental conditions, to gain new insight into their area of expertise.

Laser UT inspection can be use for:

- Hot metal inspection

- Microstructure analysis

- Additive manufacturing

- Weld evaluation

- Thin coatings characterization

- Composite inspection

Thermal and cold spray

Spray sensors by Tecnar

The use of spray sensors is the ultimate industry 4.0 quality control for thermal sprayed coatings and optimizing all spray processes.

Whether you specialize in industrial thermal spraying or thermal spray research, Tecnar’s goal is to meet your needs by:

- Ensuring quality and repeatability

- Saving time on powder or gun change

- Developing and transferring spray parameters

- Optimizing deposition rates

Automated pipe and vessel welding

Rotoweld 3.0 by Tecnar

The Rotoweld 3.0 is the ultimate automated welding solution to increase your productivity and stay competitive in today’s fabrication industry.

The technology was first developed and patented at the Canadian Research Council in the 1980s. Today, this vision-based automated control of weld pool penetration is still the most reliable, productive and consistent automated STT process for welding a standard open bevel.

Get the industry’s highest productivity output

- Typically averaging 300 dia inch per day

- Diameter capacity of 3in. to 42 in.

- Pipe stand capacity of 10,000 lbs.

Want to learn more about our technologies

We’re here to help and to answer any questions you might have. We look forward to hearing from you.